Advantages

・High Efficiency Over Full Load Range

Proprietary predictive control maintains ideal Zero-Voltage Switching (ZVS) from light to full load, minimizing power conversion losses.

・Reduced Component Costs and Miniaturization

Eliminates the need for an inductor current sensor, reducing component costs and board space. Fixed-frequency operation also simplifies and downsizes EMI filters and other passive components.

・High Design Freedom and Reliability

System reliability is improved by eliminating a physical sensor, a potential point of failure. Design freedom is increased, maximizing SiC/GaN performance by enabling the use of devices with higher parasitic capacitance (which often have lower on-resistance).

Background and Technology

In AC-DC converters, PFC (Power Factor Correction) circuits are essential for high efficiency and power factor. While bridgeless PFC was developed to solve the conduction loss issue of traditional diode bridges, it introduced a new problem of large switching losses due to hard switching.

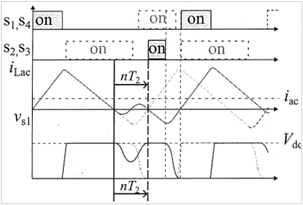

Critical Conduction Mode (CrM) control exists as a ZVS technology to solve this, but it has its own issues: “switching frequency fluctuates, leading to bulky EMI filters” and “a current sensor to detect zero-crossings is mandatory, creating cost and reliability challenges.”

This technology is a predictive ZVS control method that solves these problems. After the inductor current reaches zero, it does not rely on a physical sensor. Instead, it theoretically calculates and actively inserts the optimal idle period based on the circuit’s state. This predictive control achieves both “sensorless” operation—eliminating the need for a current sensor—and solves the frequency fluctuation problem, enabling stable, high-efficiency ZVS operation across the entire operating range.

Data

Expectations

This technology has the potential to fundamentally enhance the performance of all AC-DC converters, such as those for server power supplies, solar inverters, and EV on-board chargers (OBCs).

The core control algorithm is complete. For the practical application of this control technology, we are seeking flexible partnerships with semiconductor manufacturers, control IC manufacturers, and various power supply manufacturers, including joint research and development for product optimization or technology licensing for integration into control ICs.

Patents

Patent Pending

Researchers

Takanori Isobe (Associate Professor, University of Tsukuba)

Project ID:DD-05365