Advantages

- Using a dental 3D printer, custom-made from the patient’s own dental impressions

- Enables at-home oral rinsing, reducing burden for both patients and healthcare providers

- Lowers aspiration risk as rinsing solution does not enter the oral cavity

Technology Overview & Background

Bisphosphonates and denosumab, which are effective for treating osteoporosis, are bone resorption inhibitors that may cause a side effect called medication-related osteonecrosis of the jaw (MRONJ). The incidence of MRONJ is approximately 1 in 1,000 patients. It is diagnosed when bone exposure persists for 8 weeks or longer, and treatment primarily involves surgical resection if feasible. However, when the boundary between necrotic bone and healthy bone is unclear, there is a risk of excessive resection or residual bone. Additionally, when surgical intervention is difficult or the patient declines surgery, conservative management involving regular irrigation may be chosen instead of surgical resection. This approach aims for healing by promoting the separation of necrotic bones. In such cases, wound irrigation is primarily performed through home mouth rinsing or regular professional irrigation. However, mouth rinsing struggles to remove residual food debris, necessitating frequent clinic visits and imposing significant burdens on both patients and healthcare facilities. To alleviate this burden, oral irrigators have been developed. Conventional devices target the entire oral cavity, leading to inadequate removal of food debris from the wound site. Furthermore, since the cleaning solution flows throughout the entire oral cavity, there is concern about the risk of aspiration for elderly individuals and people with disabilities who have impaired swallowing function.

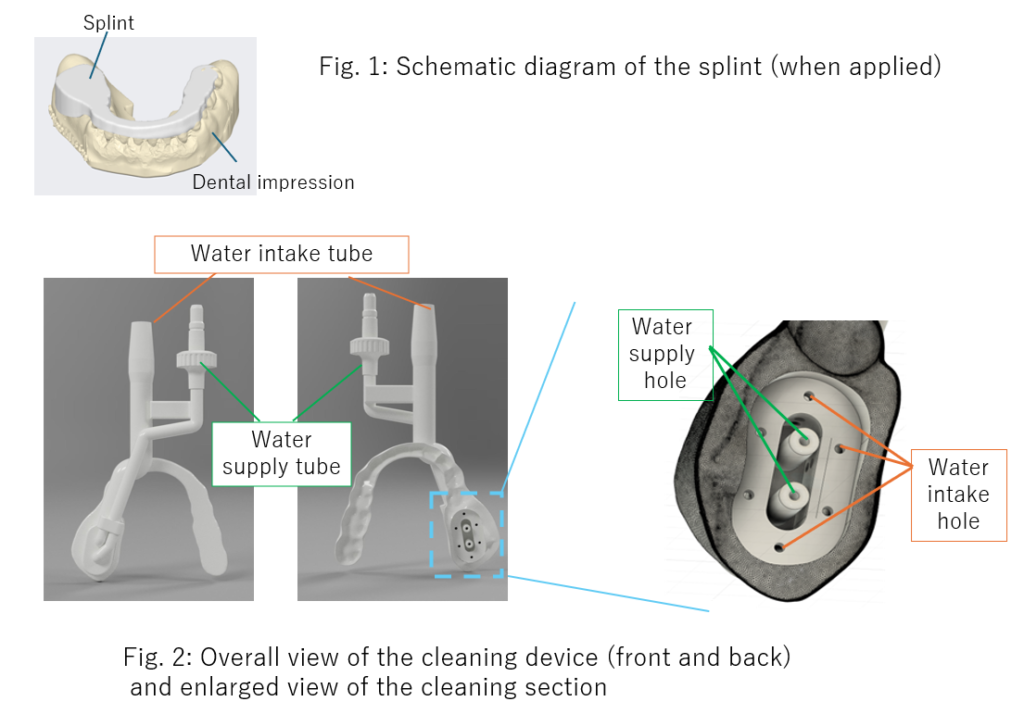

Therefore, the researchers developed a mouthpiece-type oral cleaning device that allows patients to perform localized cleaning and suction within the oral cavity themselves at home. Specifically, dental impression data is first acquired using an intraoral scanner, and then a splint covering the dentition, including the wound site, is fabricated using a 3D printer (Figure 1). Next, water delivery and suction sections are machined into the inner surface of the splint. This enables both washing and suction within the mouthpiece itself (Figure 2), preventing the washing solution from leaking outside the mouthpiece. This suction mechanism for cleansing water prevents aspiration and allows use while seated. Consequently, patients themselves, including elderly individuals and people with disabilities experiencing impaired swallowing function, can perform the cleansing at home. This significantly reduces the burden on both patients and medical institutions while also improving patient quality of life.

Data

- Using a jawbone necrosis model, performance testing was conducted on the prototype cleaning device of the present invention (Figure 3). Using 10x rice gruel, which has properties similar to residual food debris, and confirming its cleaning, it was confirmed that the debris could be cleaned with almost no residue remaining.

|

Patent(s)

Applied in Japan, not yet published.

Principal Investigator & Academic Institution

Hideyuki YAMANOTO, DDS, PhD (Assistant Professor, Nagasaki University, Japan)

Development Stage & Future Research Plans

- Further safety verification tests for the cleaning device of the present invention are currently underway.

Expectations

TECH MANAGE is seeking companies developing dental materials and instruments who are interested in this invention and willing to explore its commercialization and practical application through licensing. We are commissioned by Nagasaki University for this purpose. Direct meetings with researchers are also possible. Please feel free to contact us with any inquiries.

Furthermore, disclosure of unpublished data is possible upon signing a confidentiality agreement with Nagasaki University. Please do not hesitate to ask.

Project ID:JT-05207