Advantages

- Low environmental impact reactions; no high pressure, low temperature reactions (about 25 °C) and no deuterium gas

- High reaction performance(80-99% introduction, 80-98% yield)

- Can be used for a wide range of compounds, post-synthesis and on-demand synthesis

- Raw material, deuterated water (D2O) is reusable and easily purified from the catalyst

Background & Technology

Recently, properties that improve chemical stability and thermal properties have been found in the performance of electronic materials through deuteration. Deuteration is also attracting attention as a way to improve the properties, longevity, and power savings of light-emitting materials used in OLED panels by reducing the expansion and contraction frequency and increasing the efficiency of thermal energy, and is becoming a trend in materials development. On the other hand, all conventional deuteration processes are batch-type deuteration methods using organic synthesis processes, and the complexity and cost of treatment methods and processes have been an issue.

The laboratory has developed a deuterium-labelled compound flow synthesis system that can be processed at ambient pressure and room temperature, using a process that does not involve organic synthesis and does not produce a large amount of waste and demonstrated deuterated pharmaceutical.

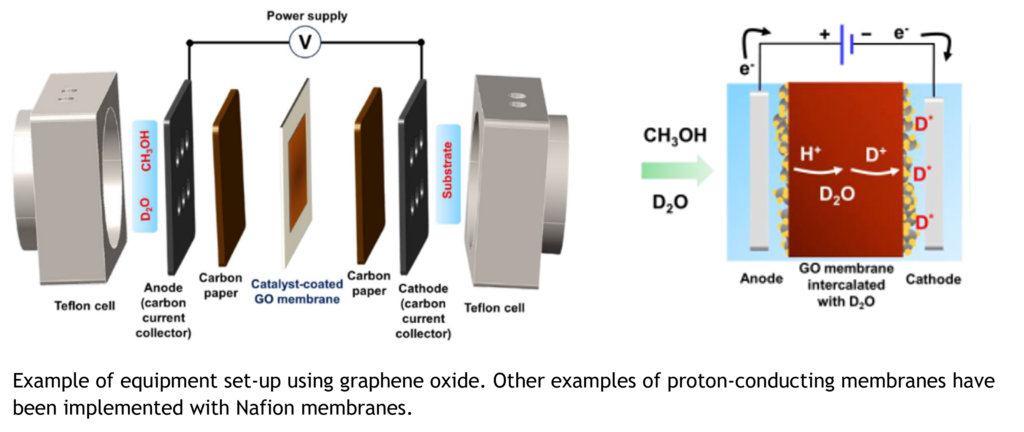

To be specific, the device concept is to supply heavy water (D2O) and a proton source to the anode side of the proton-conducting membrane and a compound to be deuterated to the cathode side of the proton-conducting membrane by means of a new membrane-type reactor with electrodes attached to the proton-conducting membrane. Nafion and graphene oxide membranes are currently used as proton-electric membranes. Deuterium-labelled compounds are electrochemically synthesized by energizing a proton-conducting membrane, whereby the proton source and heavy water are electrochemically oxidized as H+/D+ on the anode side and react with the deuterated compound as D+/D2 that passes to the cathode side via the proton-conducting membrane.

This system will contribute to the R&D/manufacturing stages of a wide range of materials, and by enabling mass production, it is likely to revolutionize the process by enabling the rapid provision of high-performance electronic materials development.

|

Researcher

Kumamoto University Department of Applied Chemistry and Biochemistry Professor Testuya Kida

Patent

Pending(International phase, unpublished)

Publication

https://doi.org/10.1021/acs.nanolett.3c04243

Development Phase

Current stage:

We have obtained a POC for a deuterated system with prototype equipment. Implementation cases and mechanism verification ongoing.

Next stage:

1-i) Evaluation of the versatility of deuterated compounds, evaluation of material development.

1-ii) Commercialization of the device through the development of mass production equipment.

2 Catalyst development, optimization and application development for further reaction efficiency.

All of the above can be done in collaboration/joint development with research laboratories. We are looking for partner companies interested in evaluating target compounds using this technology/process, joint research/development collaboration and technical guidance. We would be happy to start with a detailed description and discussion of the technology.

Project ID:ON-04951b