Advantages

- For low environmental impact mass production, a direct synthetic method of DME, which is a next-generation clean fuel in remarkable demand in Asia-Pacific region and EU.Original catalyst for DME synthesis, showing the world’s highest level of yield

- Environmentally adaptive synthesis process using CO2, CO and hydrogen

Background & Technology

DME has similar properties of liquefied petroleum gas (LPG), and is used for an aerosol propellant for sprays of dust blowers, insecticides, cosmetics, and household products. In China, DME is used as a domestic or home fuel in own or mixed with LPG. When DME burns, it has no particulate matter (PM) and no sulfur oxides (SOx) in the exhaust gas, because there is no C-C bonds and no sulfur in DME (CH3OCH3). Cetane number of DME is almost same as that of diesel oil, so DME can be used for diesel vehicles. Nitrogen oxides (NOx) and carbon dioxide (CO2) emission are smaller than diesel oil. DME is a clean fuel, and it is expected as a next-generation clean fuel. Its demand is growing, especially in the Asia-Pacific region and EU, and major applications include CO2 reduction through LPG blending and transportation fuels as a substitute for diesel oil. DME is expected to accelerate environmental regulations and the transition to cleaner fuels.

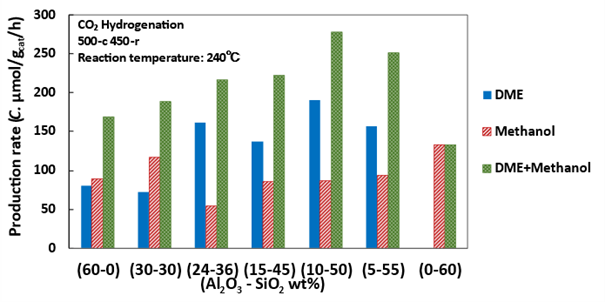

In such a market, there is a high demand for more efficient DME synthesis processes. In contrast to the “indirect method” of synthesizing DME from methanol, this laboratory has started the “direct method” of DME synthesis, which combines methanol production and dehydration reactions from carbon monoxide (CO) and CO2 with hydrogen. They have developed catalysts that contribute to process efficiency and low environmental impact. Specifically, the metal oxide catalyst Cu-Zn/Al2O3 using the sol-gel method has achieved a high DME production rate of 486 μmol gcat-1 h-1 and a DME yield of 8.0% under an atmospheric pressure and 0.9 MPaG even the low reaction pressure. The laboratory is currently developing an even more active catalyst, Cu-Al2O3-SiO2, to produce DME from CO2, and it is expected that the appropriate use of this catalyst will enable the company to meet domestic and international needs.

Data

Comparison of DME and methanol synthesis performance of Cu-Zn-Al2O3 and Cu-Zn-Al2O3-SiO2 catalysts (0.5 g) for different mass ratios of Al2O3 to SiO2.

|

Researcher

Shizuoka University, Department of Applied Chemistry and Biochemical Engineering

Associate Professor Kaoru Takeishi

Publication

K. Takeishi et al., “Promotional Effect of Water on Direct Dimethyl Ether Synthesis from Carbon Monoxide and Hydrogen Catalyzed by Cu−Zn/Al2O3”, ACS Sustainable Chem. Eng. 2017, 5, 3675−3680.

K. Takeishi, “Dimethyl ether and catalyst development for production from syngas”, Biofuels, 2010, 1, 217-226.

Development Phase

Current stage:

Demonstration of the catalyst’s ability to synthesize DME has been completed, and research is underway to elucidate the reaction mechanism.

Next stage:

(1) Performance evaluation and process development of synthetic reactions by raw material and application

(2) Development of mass production equipment for DME synthesis

We are looking for partner companies interested in the practical application of this catalyst and synthesis process, partner companies interested in joint research and joint development for reaction evaluation and DME mass production by application, and companies interested in expanding overseas sales channels. We would be happy to start with a detailed explanation and discussion of our technology.

Project ID:ON-05263