Summary

- New binder-free, yellow-green, single-crystal YAG phosphor with high conversion efficiency and thermal stability for high-brightness white light sources.

- Higher output power than that of conventional products is possible.

- No cooling system is required, enabling downsizing of equipment.

- This crystal sample is available for evaluation.

- We are looking for companies interested in developing lasers and LEDs using this invention.

Technology Overview & Background

In recent years, white lighting that uses phosphors with blue LEDs as the excitation light source has become popular due to increased awareness of energy conservation and environmental protection. Conversely, products that use blue laser diodes (LDs) as light sources are gaining popularity in applications such as projectors and headlights, where high brightness is required and difficult to achieve with LED light sources. However, as LD light sources become more powerful, they become less efficient at high temperatures, making heat dissipation difficult. Additionally, the conventional YAG phosphors are manufactured using sintering technology, which lowers luminous efficiency at high temperatures. Furthermore, when using powder phosphors, binders with low thermal conductivity, such as resins, are required. This causes a temperature rise problem and prevents sufficient performance in high-power applications.

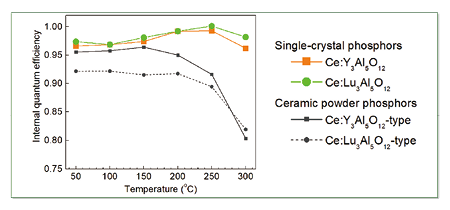

In contrast, the inventors developed a new YAG single-crystal phosphor that has an internal quantum efficiency greater than 0.9 at room temperature. There is almost no degradation of the internal quantum efficiency at 300°C (see figure below). This phosphor is made using the Czochralski method, which maintains excellent luminescence properties even at high temperatures. The temperature rise of the material itself is minimal, which greatly reduces the problem of heat generation.

Additionally, single-crystal phosphors do not contain binders or impurities required for powdered phosphors. Consequently, heat dissipates more easily, and cooling devices are unnecessary, which contributes to equipment miniaturization. Furthermore, improved heat dissipation reduces the temperature increase compared to conventional phosphors, enabling higher luminance and power. This technology is expected to overcome conventional problems and contribute significantly to improving the performance of white lighting products and downsizing equipment while saving power and reducing manufacturing costs.

- Point 1: Achieve a higher luminance than is possible with conventional powder phosphors.

- Point 2. The temperature rise of the phosphor is smaller than that of conventional powder phosphors, enabling the cooling system to be miniaturized.

- Point 3: The power consumption of the entire package is reduced.

à The above characteristics enable higher luminance than can be achieved with conventional powder phosphors in a smaller size with less power consumption. - Point 4: Even at the high luminance that can be achieved with conventional powder phosphors, compactness and power savings are possible.

Data

- The internal quantum efficiencies of YAG single-crystal phosphors and conventional sintered YAG powders were examined as a function of temperature. It was found that the efficiencies decreased with increasing temperature for sintered YAG powders, but not for YAG single-crystal phosphors.

|

| Comparison of YAG single-crystal phosphor (Ce: Y3Al3O12) and conventional sintered YAG powder phosphor in internal quantum efficiency (Ce:Lu3AI3O12: cerium doped lutetium) |

Patent(s)

Patent filed and submitted in Japan, US and EU

Principal Investigator & Academic Institution

Kiyoshi Shimamura, NIMS(National Institute for Materials Science)

Expectations

The National Institute for Materials Science (NIMS) is looking for companies interested in developing lasers and LEDs through a license for this invention. In addition to arranging direct meetings with our researchers, we can share unpublished data and other information by signing a confidentiality agreement with NIMS. We can also provide samples of the invention’s crystals for evaluation. Please feel free to contact us with any requests.

Project ID:DA-05155