Advantages

- It is possible to synthesize peptides that were difficult to synthesize using conventional methods due to steric hindrance.

- High yields can be achieved in a short time using only inexpensive reagents.

- No excess amounts of reagents or substrates are required.

- Such peptides are expected to have pharmaceutical efficacy, oral bioavailability, cell membrane permeability, and metabolic stability.

|

Current Stage and Key Data

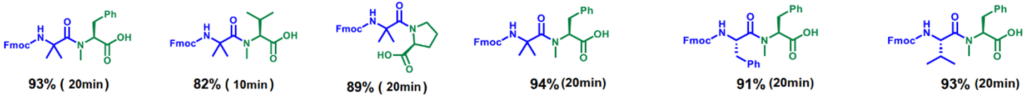

- Dipeptides have been synthesized from various substrates with high yields confirmed.

|

|

Partnering Model

Seeking joint development partners for peptide pharmaceuticals and agrochemicals using this synthesis method, as well as license partners for this synthesis method.

- Examples of potential partners: CMC departments of biotech/pharmaceutical companies developing peptide pharmaceuticals, peptide agrochemical companies, CMO/CDMO for peptide pharmaceuticals/agrochemicals, chemical companies focusing on flow synthesis.

Background

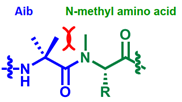

N-substituted amides with a substituent (e.g., methyl group) on the nitrogen of the amide bond are attracting attention as drug candidate molecules because they may have high biocompatibility, cell membrane permeability (e.g., LUNA18, in clinical trials).

In peptide synthesis, the condensation and deprotection steps of protected amino acids are generally repeated, which increases the synthetic effort, time, and amount of waste. For this reason, it is considered important to develop a method for linking free amino acids consecutively. It would be ideal if peptides could be synthesized by consecutively linking bulky free amino acids such as N-substituted amino acids. However, the previously reported method of reacting bulky N-substituted amino acids with bulky C-terminus to extend bulky amide bonds has been difficult to apply industrially due to expensive reagents, excessive substrates, toxic reagents, long reaction times, and low yields.

Principal Investigator

Shinichiro Fuse (Department of Basic Medicine Science, Graduate School of Pharmaceutical Sciences, Nagoya University, Tokai National Higher Education and Research System)

Reference

Papers: Unpublished, Patents: Pending *Additional information may be disclosed under CDA.

Project ID:BK-04861