Summary

- The device can apply an unprecedentedly high shear rate (105-107[1/sec]) to a sample by using a device to make the sample thinner and a vibration mechanism using a piezo.

- The window makes it possible to observe the deformation from the outside using X-rays, infrared rays, or a microscope.

- It can be applied to measure rheological properties of a wide range of samples, from low-viscosity liquids to high-viscosity gels, and even solid rubbers.

- Proposal to introduce this technology to companies developing rheological measurement devices such as viscometers and rheometers

Technology Overview & Background

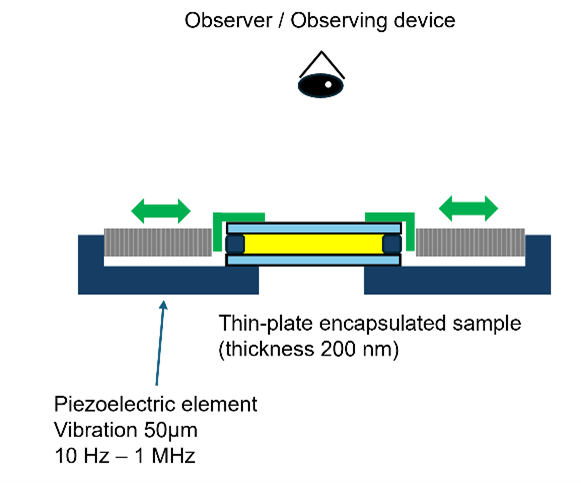

In response, Dr. Akada and his colleagues at the Tsukuba University have developed a shearing device (right figure) that enables high-speed, high-impact shearing for a wide variety of samples. In this shear device, a sample is held between substrates connected to a piezoelectric actuator, and one of the substrates vibrated at high speed against the other. By making the sample very thin (100 nm to 1 μm), a high shear rate of 105 to 107 [1/sec] can be applied, compared to the shear rate <103 [1/sec] of a typical rheometer. And because a window is provided in the center, the thin film sample can be observed from the outside.

This technology can apply a forced shearing force to thin-encapsulated samples. Therefore, the target of measurement extends to liquids, highly viscous materials, and solid materials such as rubber. In addition, since various observation methods, including optical measurement, can be employed, the technology is expected to be applied to the measurement of various rheological properties.

One of the applications of this technology is coating technology. Coatings are used not only for printing and modifying plastic and metal products, but also in cutting-edge technologies such as optical films, application of electrode materials for batteries, and semiconductor technology. In advanced coating technology, which requires the formation of very thin films, extremely strong shear forces are exerted between the nozzle or coating surface and the material to be coated, which are difficult to reproduce or observe without this technology. This technology has great advantages in the development of such state-of-the-art coating technology.

Patent(s)

Patent pending (not yet published)

Principal Investigator & Academic Institution

Keishi Akada (Researcher, Japan Synchrotron Radiation Research Institute)

Expectations

We are looking for companies that are manufacturers of viscometers, rheometers, and other equipment for measuring rheological properties to consider commercialization and application of this technology through introduction. We can provide you with information and knowledge through the following steps and can consult with you on how we can assist you in considering and commercializing the introduction of this technology in your company. We can also arrange a meeting with the developer. If you have any requests, please feel free to contact us.

- Exchange information to help you understand the principles and characteristics of technology.

- Detailed explanation by meeting with the developer.

- Exchange of information under NDA

- Technology development through joint research, etc.

- Patent licensing for commercialization

Project No.DA-04949