Summary

- A friction welding technology that enables joining at temperatures below the temperature at which crystal transformation does not occur by the application of appropriate pressure and maintains the same strength as the base metal.

- It has been proven that there is little deterioration in strength even when joining metals of different types (dissimilar material joining).

- It can also be applied to linear friction welding, and a device that uses an electric motor for the linear sliding mechanism has also been developed, achieving significant downsizing and cost reductions.

- We propose the introduction of this technology to manufacturers of joining equipment and to companies in the automotive and railroad industries that use joining equipment.

Technology Overview & Background

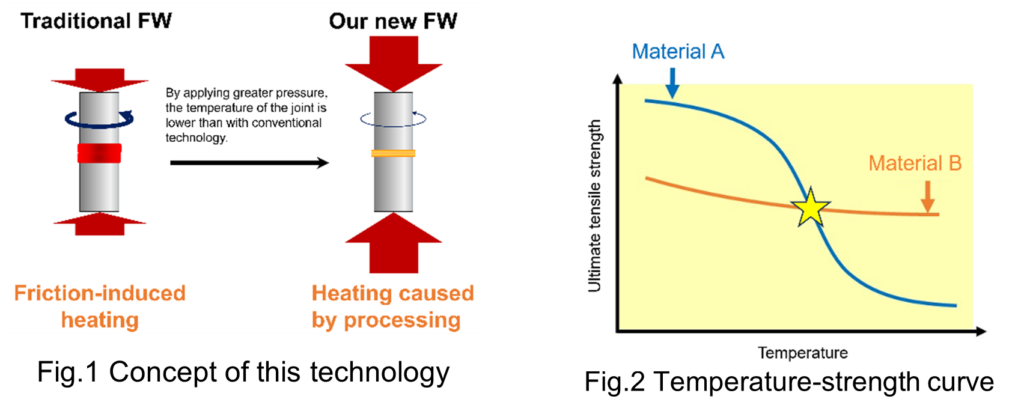

Friction welding is a technique for joining two cylindrical materials by heating them using frictional heat generated by rotating them while pressing them against each other (Figure 1). Compared to conventional fusion welding, this technique is widely used because it reduces the strength deterioration of the joint, but it does not completely prevent the deterioration of the joint.

Professor Fujii of The University of Osaka has developed a new technology to solve this problem. This technology reduces strength deterioration of joints to zero. By applying sufficient pressure at a low rotational speed, the temperature of the bonding surface can be kept below the crystalline transformation point (A1 point) while the materials are in a solid state (Figure 1). This suppresses degradation in the bonding area, making it difficult to destroy the strength process of the material.

|

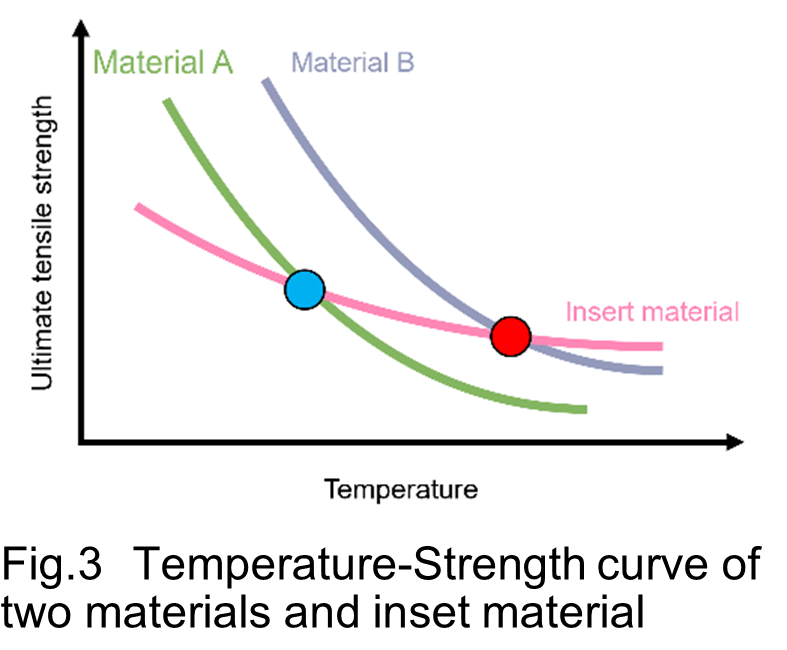

Furthermore, this technology can be applied to joining different materials. First, examine the “temperature-strength curves” of each material. Next, find the temperature at which the curves intersect (see Figure 2). Then, apply a pressure to the material equal to the strength corresponding to this temperature. The two materials then reach the same temperature and begin to deform simultaneously, eventually joining. If the “temperature-strength curves” of the two materials do not intersect, insert material C between materials A and B. The “temperature-strength curve” for the insert material is shown in Figure 3. The left white circle in Figure 3 is the intersection of material A and insert material C, and the right white circle is the intersection of insert material C and material B. In other words, if the aforementioned method is applied, A and C are first joined by applying pressure P1 at a temperature of T1. Then, C and B are joined at a pressure of P2 where the temperature reaches T2. Then, A, C, and B are joined together, and the strength of the joint is the same as that of the base metal or almost no deterioration.

This technology can also be applied to linear friction welding (LFW), where the same material can be joined below the A1 point temperature to create a joint with almost no strength degradation. Even when joining different materials, if appropriate conditions are found as described above, joining can be performed with minimal strength degradation.

|

In addition, we propose a new technology for linear friction welding. Conventional LFW uses a hydraulic device to vibrate the materials to be joined at high speeds, but the device is expensive and very large, creating a high barrier to introducing the technology. Professor Fujii has developed a new device that solves this problem. The device is a friction stir welding device driven by an electric motor and applying linear vibration. Compared to the conventional hydraulic type, it enables significant downsizing and cost reduction.

Data

Stainless steel (SUS316L) and titanium alloy (Ti-6Al-4V (Ti64)) were joined by linear friction welding by applying a pressure (400 MPa) equivalent to the joining temperature at which both materials reach the same strength.

Aluminum (A7075-T6) and steel (S45C) were linear friction welded using nickel (pure nickel) as an insert material at 300 MPa for aluminum and nickel and 50 MPa for steel and nickel. It was confirmed that both materials deformed at the respective bonding interface, ejecting burrs and joining.

Patent(s)

WO2017/022184、WO2018168687、WO2021200504A1

Principal Investigator & Academic Institution

Prof. Hidetoshi Fujii The University of Osaka, Joining and Welding Research Institute

Expectations

- If any company is interested in developing a joining device that incorporates this technology, we propose to develop the device in collaboration with The University of Osaka. We can also provide technical guidance for practical application.

- If any company (automotive, railroad, etc.) needs a joining device using this technology, please contact us. We will propose a joint research and development system with The University of Osaka to see if it is possible to join the metals used by your company.

- We are available for direct meetings with researchers regarding this invention/project, so please feel free to contact us if you have any requests.

Project No.DA-01012b