Advantages

- With pretreatment device that selectively removes ions (99% removal rate)

- Measurement time is ~60s as same as normal ICP-MS instruments

- No change in particle size distribution due to ion removal process

- Significantly improved lower limits of detectable particle size

Background & Technology

Although dynamic light scattering, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) have been used to measure nanoparticles, recently, ICP-MS has been attracting attention as a method that can selectively detect specific metal particles. Nanoparticles contained in sample solution are ionized by plasma and detected in time analysis (TRA) mode (SP-ICP-MS). The TRA data are then converted to Particle size and Normalized Frequency data to obtain particle concentration, particle size, and particle distribution. Meanwhile, when the same metal exists in the sample solution as a ionic solutes along with the metal particles to be analyzed, the background becomes large, and the measurement accuracy of the particle signal is reduced. As means to improve such issues, a method to statistically process the measurement data and separate the particle signal from the ion signal has been reported, but it has limitations as an improvement measure.

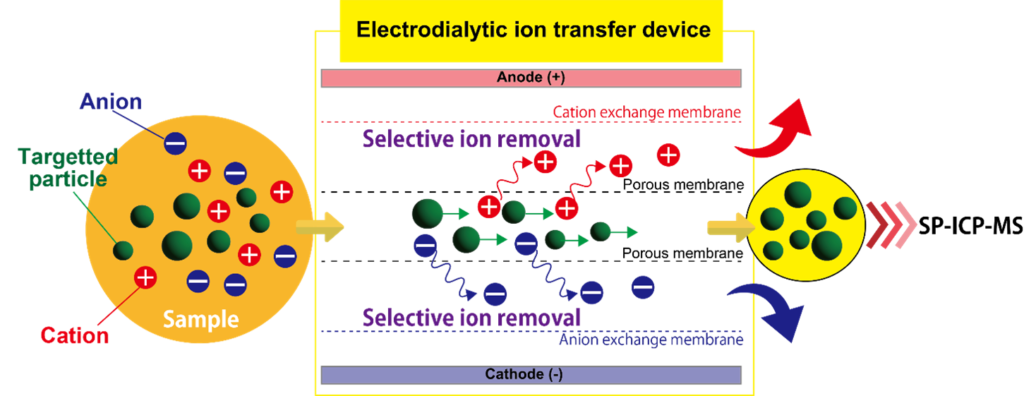

This invention is a “SP-ICP-MS system with particle purification device” that solves these problems by extracting and removing ionic solutes from a sample solution and analyzing the purified particles as the target sample. Specifically, it is an instrument equipped with a dissolved ion extraction device (ITD) as a pretreatment device, which selectively removes ions from the sample solution by ion diffusion/electrophoresis and membrane transferring.

|

Data

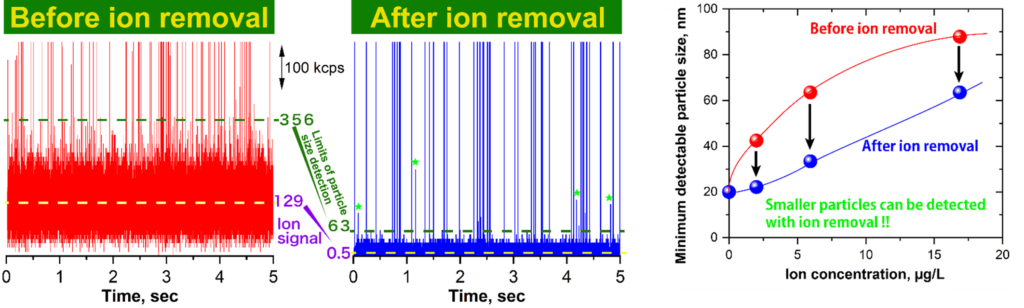

Dissolved ion extraction device removes Al ions in-line to introduce particles (Al2O3) directly into ICP-MS

Quantitative removal of Al ions from the particle dispersion improves the lower limit of detectable particle size, enabling more accurate detection of smaller particles.

|

Researcher

Kumamoto University, Faculty of Advanced Science and Technology, Professor Shin-Ichi Ohira

Patent

Pending(unpublished)

Publication

The 72nd Annual Meeting of the Japan Society for Analytical Chemistry

Development Phase

This stage :

Completed demonstration of extraction efficiency of dissolved ions and particle residuals by prototype equipment.

Next stage:

- Removal replicability and performance optimization with ICP-MS manufacturer for commercialization realization.

- Industrialization of this product through scale-up development.

Both of the above are available for collaboration research / co-development with our laboratory. 2. is desired to be considered by partner companies mainly.

We are looking for partner companies interested in evaluating samples using this technology/process, joint research/development collaboration, and technical guidance. We would be happy to start with a detailed explanation and discussion of the technology.

Project.ON-04900