Advantages

- There is almost no need to change the size or type of bullet depending on the object.

- There is no need for a force sensor or its frequency analysis.

- The peak value of excitation force is high, and even a small bullet can apply a large impulse.

- Measurement accuracy does not deteriorate because double striking does not occur.

- Capable of measuring vibration characteristics of rotating bodies.

Background and Technology

In general, it is better for mechanical structures such as machine tools to be less susceptible to vibration, so it is important to measure vibration characteristics. Conventionally, an impact (impulse) hammer with a built-in excitation force sensor has been used to measure vibration characteristics. In the vibration test, the tester manually hits the object to be measured (mechanical structure) with an impact hammer, and the vibration force at the time of the impact is measured by a vibration force sensor. At the same time, the vibration of the object is measured using a three-axis accelerometer or the like attached to the object to derive a compliance transfer function. An ideal impulse (excitation force) has an infinite peak force and zero time width, but a hammer of a certain size is required to produce sufficient excitation with manual hammer striking. In that case, the time width becomes longer and the high frequency excitation force becomes smaller. Therefore, accurate measurement of the excitation force waveform and correction based on the analysis results are performed. It is necessary to select from multiple types of hammers and tips suitable for the object. The harder the tip, the shorter the time span, but there is a risk of leaving dents on the object. Furthermore, the weight of the hammer needs to be adjusted according to the weight of the object. If it is too heavy, double striking will occur and the measurement accuracy of a specific frequency will be reduced, and if it is too light, sufficient excitation force will not be obtained. Furthermore, it is difficult to measure a rotating body because it is difficult to hit it with a hammer while it is rotating.

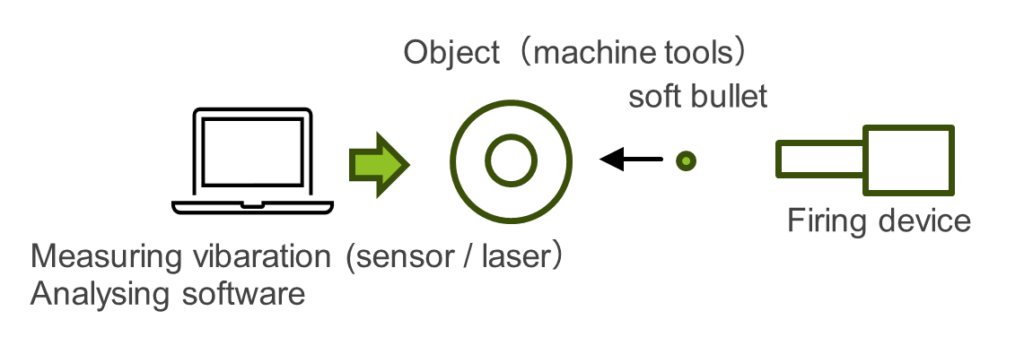

The feature of this technology is that a soft bullet (e.g. BB bullet) with a diameter of several millimeters, which is smaller than a hammer, is fired at high speed into the object excite it. The bullets are made of hard resin or soft metal, which are softer than the object, and do not leave any marks. Since the time width of excitation decreases in proportion to the size of the bullet, substantially ideal impulse excitation can be performed by making the bullet sufficiently small relative to the object. Therefore, there is no need to prepare various impact hammers or excitation force sensors, and there is no need to measure and analyze the forces. Further, double striking does not occur, and it is easy to measure rotating bodies.

|

Principal Investigator

Eiji SHAMOTO (Graduate School of Engineering, Naogoya University)

Current Stage and Next Step

- Currently, the concept has been proven in the laboratory by measuring the vibration characteristics of stationary and rotating bodies using BB bullets.

- We are looking for partner and user companies to work on the practical development of systems including soft impact bullets, firing devices, vibration sensors, and analysis software.

Project.BK-04887