Advantages

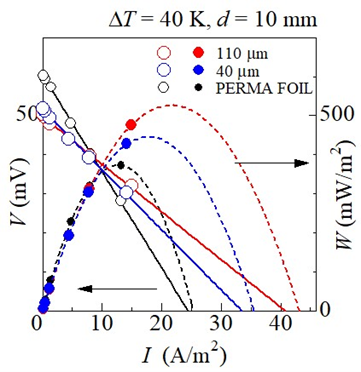

- High power generation with electrode proximity by alcohol solvent : Electrolyte using alcohol solvent with low thermal conductivity produces a large temperature difference between electrodes with a small heat flow, resulting in a higher electromotive force efficiency than water electrolyte

- High power generation by low-resistance and large-area electrodes of paste type : Low-resistance electrodes with flexible shapes can be manufactured simply, cost-effectively, and over a large area by applying a carbon powder-containing agent to the surface of the resin.

- Used for stand-alone distributed power supplies for IoT sensors, power conversion of waste heat near room temperature, and power supplies for wearable devices that use body heat.

Technology Overview & Background

Thermoelectric cells have attracted attention as one of the energy harvesting technologies that convert temperature differences in the environment into electrical energy. Thermoelectric cells using aqueous solution as the electrolyte have been studied, but the temperature difference between electrodes cannot be increased with a small heat flow. By using alcohol (or adding a prescribed amount of water), which has lower thermal conductivity than water as a solvent for the electrolyte, the researcher has fabricated a thermoelectric cell that can generate a large temperature difference between electrodes even with a small heat flow, resulting in high electromotive force. Alcohol has lower thermal conductivity than water, so not only can the distance between electrodes be made closer and the device thinner, but also the power generation efficiency can be higher.

The electrode, which was conventionally in sheet form, is formed by directly applying a carbon powder-containing agent to the inner surface of an electrolyte housing made of a flexible resin or other material. The fabricated electrodes are not only flexible in shape, but also have high performance (low resistance) and can be manufactured with a simple structure at low cost. The electrode area can be enlarged for wearable applications, which further increases the output power.

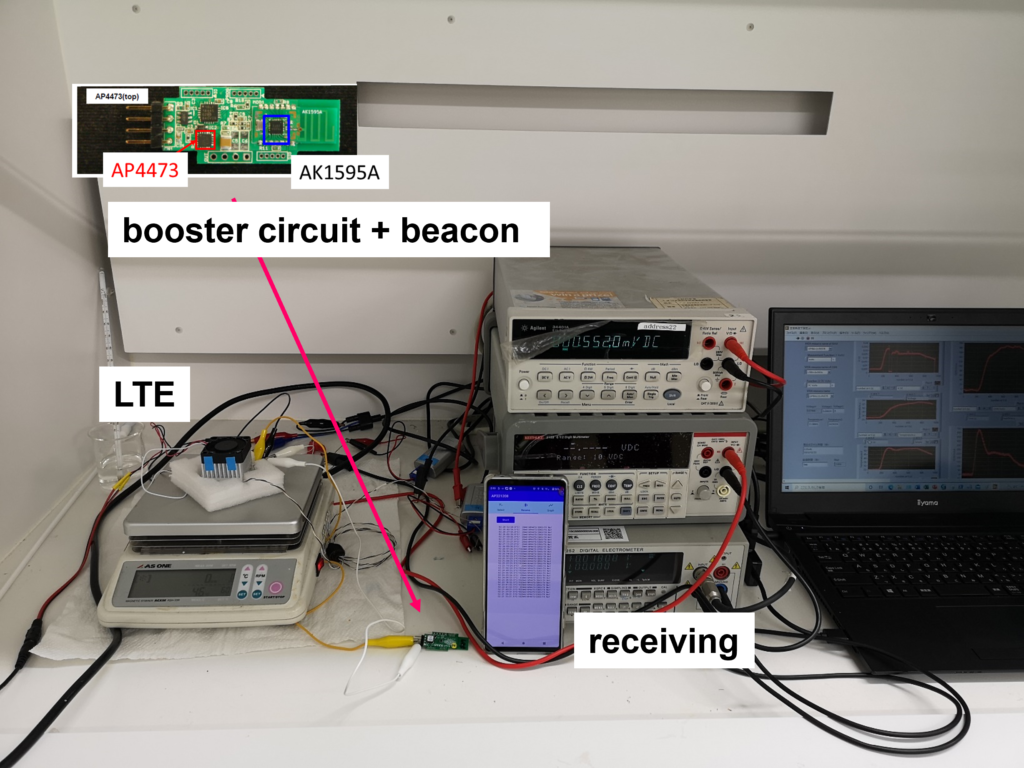

The liquid thermoelectric cells of this technology are used for stand-alone distributed power supplies for IoT sensors, power conversion of waste heat near room temperature, and power supplies for wearable devices that use body heat.

Data

Publication

- Thermoelectric generator with alcohol solvent

- Wake, D. Inoue, and Y, Moritomo, ” Liquid thermoelectric conversion devices composed of several organic solvents” Jpn. J. Appl Phys., 62, 014002 (2023).

- Wake, D. Inoue,and Y. Moritomo, “A liquid thermoelectric device composed of organic solution”, Appl. Phys. Express, 15, 054002 (2022).

- Paste type electrode

- The 71st JSAP Spring Meeting 2024, “Coated Electrodes for Liquid Thermoelectric Conversion Devices” (K. Aiba et al.)

Patents

pending

Principal Investigator & Academic Institution

Yutaka MORITOMO

(University of Tsukuba, Institute of Pure and Applied Sciences, Professor)

Expectations

We are looking for companies interested in this invention technology. We can disclose unpublished data, etc. by concluding a nondisclosure agreement with the University of Tsukuba, and we can also arrange a meeting with the inventor. If you have any questions or requests, please contact us anytime.

Project.HK-04788