Advantages

- Fine mineral particles lost in present mineral processing can be recovered.

- Protein structure is versatile with variable metal-binding module.

- Selective metal-binding peptide can be acquired by phage display methods.

- Speedy handling is possible in adsorption, agglomeration, and recovery.

Background & Technology

In the metallurgical smelter process, mineral processing is important part to separate target and valuable minerals from non-target and valueless ones. Mineral ores are crashed to small particle of minerals with single component, and then small particles are separated depending on their physical properties (specific gravity, magnetic property, hydrophobicity, etc.), leading to the separation of valuable metals from other mineral particles that have no economic value. Crashing to fine particles is effective to improve the purity in mineral processing. However, very fine particles cannot be recovered in mineral processing such as floatation, resulting in 10% loss of the total mineral content. Therefore, recovering technique should be developed to recover the finer mineral particle with high selectivity in economic and environmental viewpoint. Several agglomerating agents have been developed to agglomerate fine and small particles, however, low selectivity still remains in these chemical-based methods.

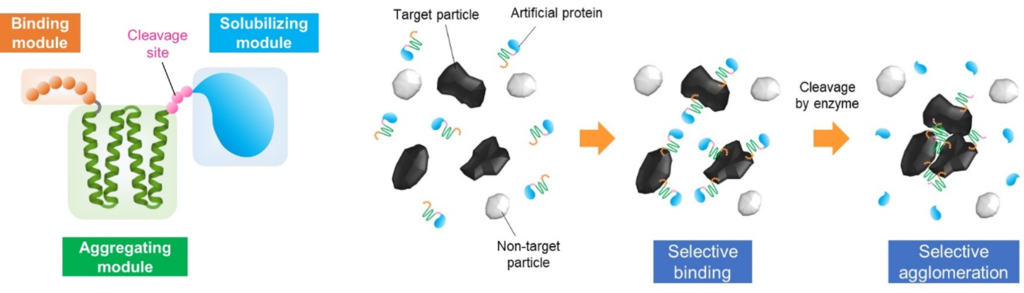

We have developed bio-based selective agglomeration system using artificial proteins to separate valuable minerals from multi-component mineral mixture. The artificial protein consists of the following three components.

(1) Highly selective metal/mineral-binding peptides (binding module)

(2) Aggregative protein to facilitate the agglomeration of particles in water (aggregating module)

(3) Highly water-soluble protein to increase solubility in water (solubilizing module)

(4) Cleavable peptide sequence by site-specific enzyme to remove solubilizing module to induce agglomeration of target metal/mineral particles.

|

Data

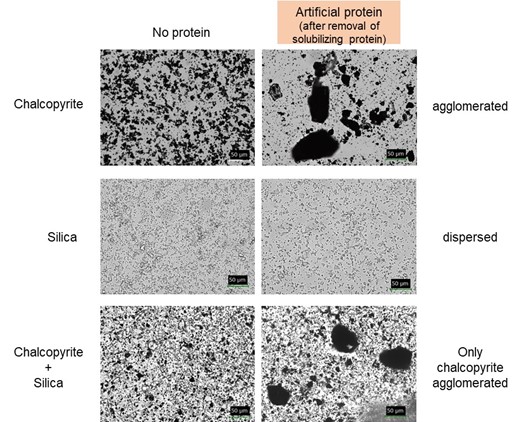

Agglomeration of chalcopyrite particles (10 mg/ml, 3-4 μm in diameter) by artificial protein composed of chalcopyrite-binding peptide and hydrophobic protein after removal of highly-water soluble protein by site-specific proteolytic enzyme. The timing of agglomeration of the particles can be controlled.

|

Patent

Pending

Researcher

Hokkaido University

Faculty of Engineering, Sustainable Resources Engineering,

Associate Professor Kazunori Nakashima

Development Phase

This stage: Demonstration of the concept of artificial protein (completed)

Next stage:

(1) Demonstration of usability in actual mineral processing including the agglomeration of target particles (in progress)

(2) Examination of optimum procedures and processes to achieve efficient recovery

(3) Large scale production of artificial proteins

We are looking for research partners interested in the present technique and the collaboration for the application/development of this method. We would be happy to start with a detailed explanation and discussion.

Project No. ON-04770