Advantage and Core Benefit

- Blended polymer made by kneading biomass-derived materials into bioplastic polylactic acid (PLA)

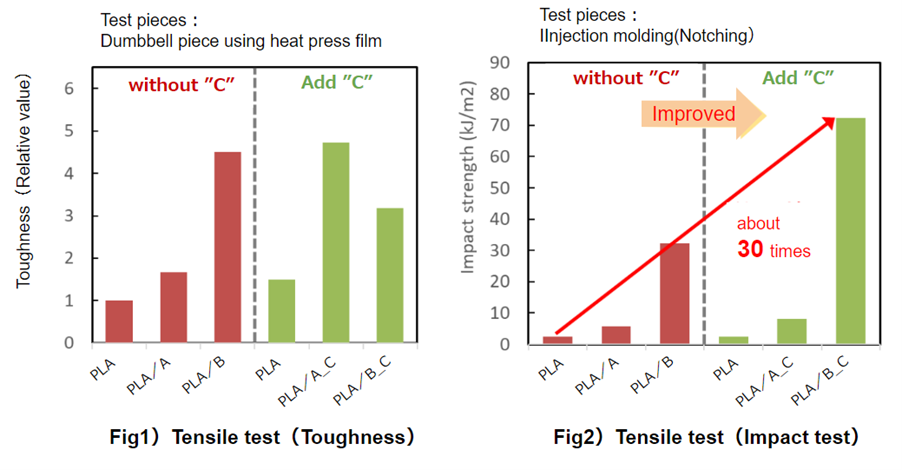

- More than twice the impact resistance of ABS resin and about 30 times more than PLA alone

- Possibility of replacing petroleum-derived ABS resin as a biomass-derived material

Background and Technology

PLA is a bioplastic in various fields but has weaknesses such as low-impact resistance and flexibility. Therefore, additives are used in combination, but most of the additives are petroleum-derived, so the biomass-derived characteristics of PLA are not fully utilized.

In addition, although it is possible to improve the impact resistance and flexibility of polylactic acid using only biomass-derived materials such as polylactic acid and natural rubber,In general, polymer blends are incompatible in many cases, and it is difficult to expect to improve physical properties as designed.

Therefore, the inventor kneaded PLA with a biomass-derived material at a specific ratio by dynamic cross-linking and further devised it to improve impact resistance and flexibility.

Data

Addition of plasticizer improves impact resistance

(Approx. 30 times that of PLA alone)

|

Expectations

Request for joint research or licensing for commercialization

Patent

Patent pending

Primary Investigator

Hiroshi Uyama

The University of Osaka Graduate School of Engineering Department of Applied Chemistry, Professor

Project No: DD-04152