Advantages

- Maintains a sufficiently thick gel shape (5-10 mm), enabling culture of high-quality cells

- Easy to control pressure, gel stiffness and culture fluid flow rate suitable for the target organoids

- Demonstrated in culture of hepatocyte cells and pancreatic cells

- Easy to improve for mass production and closed systems

- Planning to culture in 96 wells for screening

Background & Technology

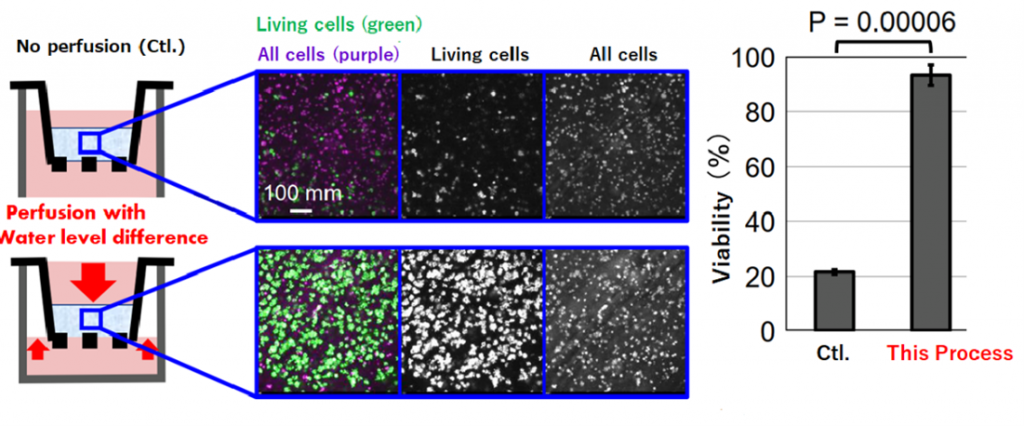

As regenerative medicine based on vaccine development and stem cell differentiation and culture becomes more active, the “perfusion culture method” is being used for stable and efficient cell culture while reproducing the natural flow of body fluid under in vivo conditions. Among perfusion cultures, the need for 3D cell culture is increasing in terms of culture efficiency, reproduction of biological cell shape, and differentiation potential. Gels such as collagen are used as the substrate for 3D cell culture, but in the conventional perfusion culture method, the substrate is deformed by the pressure exerted by the pump used for perfusion, and cells cannot be properly maintained. When the substrate was deformed, it was difficult to realize cell culture that reproduced the internal environment of the tissue.

This technology introduces the idea of a fundamental structural change to address these issues. This is the “water level difference perfusion culture method”. This system is a culture medium perfusion method in which a pressure difference is generated between the first culture medium and the second culture medium by the difference in water level to allow the culture medium to permeate the substrate. Since the pressure can be controlled by adjusting the size and density of the holes at the bottom of the substrate, the pressure applied to the substrate can be adjusted to maintain the thickness of the gel substrate, enabling 3D culture. Conventional 3D culture uses a substrate of about 1 mm thick, but this technology has been shown to culture with a substrate of 5-10 mm thick.

The device is also intended for use in organoid culture of mesenchymal stem cells and other organoid cells. Organoid culture requires controlled culture conditions for each target tissue/culture period. Since this process can control the thickness, stiffness, and flow rate of the substrate, it can be optimized for a wide range of future cultures. In addition, the possibility of scale-up for mass production has been demonstrated with the syringe perfusion system.

| Culture results in hepatocyte model cells (HepG2 cells)

|

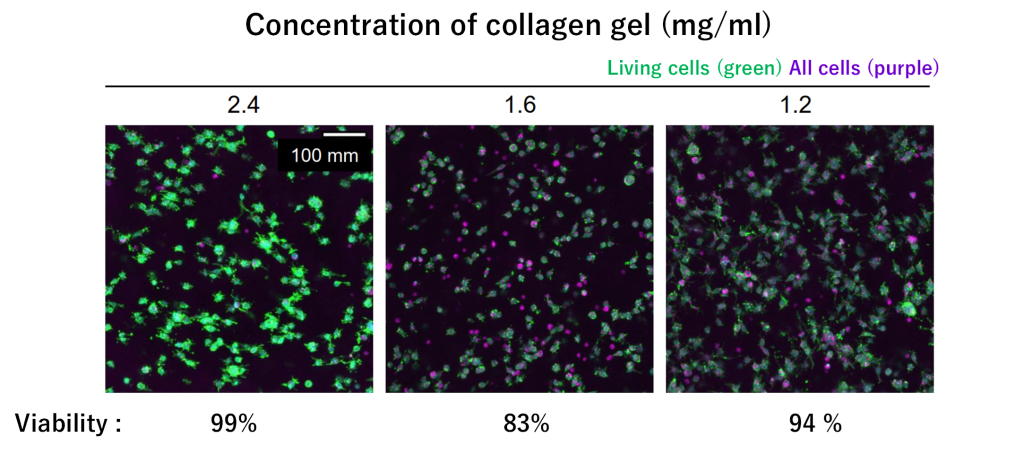

Data

- Left:Culture of hepatocyte cells (HepG2 cells) in different thicknesses of collagen gel substrates. Successfully performed hydraulic perfusion culture with thicknesses up to 10.0 mm.

- Right: Culture of hepatocyte cells (HepG2 cells) with different collagen concentrations; more than 80% of cells survived in collagen gels with concentrations of 1.2-2.4 mg/mL.

|

|

Patent

Pending

Researcher

Hokkaido University Graduate school of life science Seiichiro Ishihara, Sumire Ishida-Ishihara, Hisashi Haga

Development Phase

This stage :

Basic structure of water level difference perfusion culture and laboratory level demonstration and syringe perfusion culture have been completed.

Next stage:

- Differentiation and culture evaluation and optimization in desired cells and organoids

- Development of a practical machine for syringe perfusion culture

- Establish a culture screening system by creating and demonstrating 96-well perfusion culture wells

We are looking for collaborative partners interested in collaborating on 1-3 above. We would be happy to start with a detailed explanation and discussion of the technology.

Project No. ON-04311