Advantages

- Enables methane production at 1/2 the amount of H2 used in the standard process

- A process that promotes “methane production from CO2” and “solid carbon capture” at a higher conversion rate

- Equipment incorporating H2 and CO2 recycling process through membrane separation

Background & Technology

The increasing atmospheric carbon dioxide (CO2) levels are becoming a global concern, which has prompted researchers to advance the technologies for CO2 reduction to meet Japan’s 46 % CO2 reduction target for FY2030 and net-zero CO2 emissions by FY2050. Against this backdrop, the development of technologies for “zero-emission thermal power generation” with no CO2 emissions and “CO2 recycling” has been gaining momentum. One strategy for “CO2 conversion to resources” is to convert CO2 into methane, which can be used as a fuel. However, the methanation process has challenges in terms of procurement volume and cost because of the large amount of hydrogen used, which is in increasing demand as a next-generation energy source. Furthermore, CO2 generation is observed upon the consumption of produced methane hence, innovative process engineering is required to avoid the re-generation of CO2.

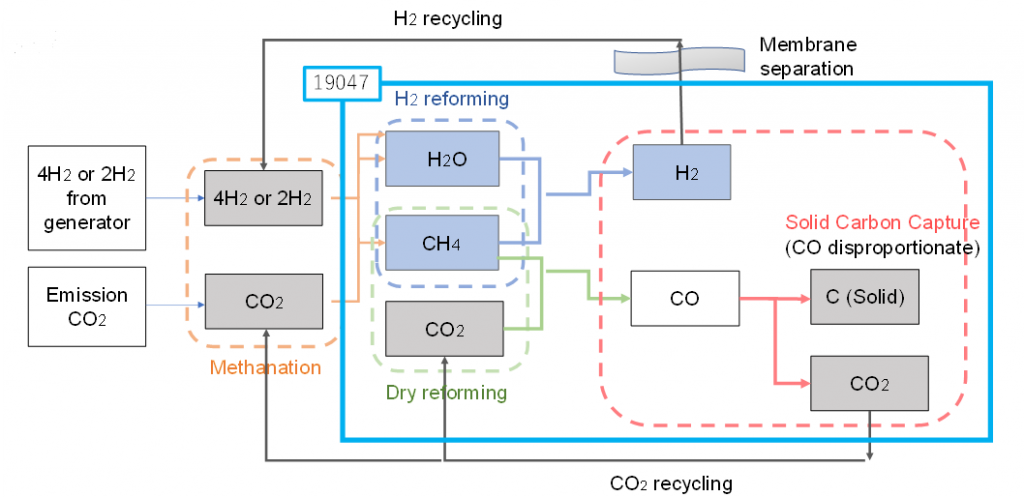

The research group found that when the amount of hydrogen used for methane conversion was reduced to half of its original concentration, the amount of remaining CO2 was increased, and methane gas in this excess CO2 state significantly improved the dry reforming efficiency in comparison to the conventional method. Based on the aforementioned key principle, the technology was developed: “methane conversion with half the amount of hydrogen and solid carbon conversion from the produced methane” and “hydrogen and CO2 recycling equipment through membrane separation”.

|

The illustration shown below is a conceptual chart of this technology. The 19047 invented by the same researcher shows a continuous treatment system of “methane conversion and dry reforming” and “continuous carbon capture” with almost no catalyst degradation, and the present technology is an improvement of the 19047.

Data

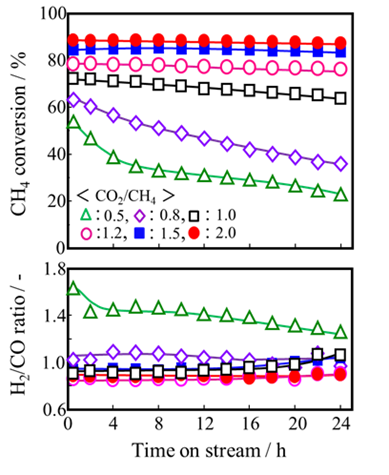

Relationship between CH4 conversion, emissions H2/CO ratio and reaction time

It was confirmed that the CH4 conversion rates at higher CO2/CH4 ratios of 1.2, 1.5, and 2.0 were higher than the CH4 conversion rate with CO2/CH4 ratio equivalent to 1.0, the amphoteric ratio of the dry reforming reaction.

This confirms that the dry reforming reaction can proceed efficiently and for a long time by using a gas with a relatively higher CO2 ratio discharged from the methanation reactor.

|

Patent

Pending

Publication

Fukuhara et al.; J. of CO2 Utilization, 22 (2017) 91/ Chemical Engineering Journal Advantages, 5(2021) 100057

https://www.sciencedirect.com/science/article/abs/pii/S2212982017304912

Fukuhara et al.; Applied Catalysis A: General 492 (2015) 190-200

https://www.sciencedirect.com/science/article/abs/pii/S0926860X14007467

Researcher

Professor Choji Fukuhara

National University Corporation Shizuoka University, Graduate school of Science and Technology

Expectations

We are looking for companies interested in developing practical applications for this methane production and solid carbon recovery equipment, or for partners interested in developing the CCU and CCUS processes.

Project No. ON-04195