Background

X-ray microscopy is a non-invasive observation technique with high spatial resolution and is used in various fields such as development of semiconductor, battery, chemical material, and medicine, etc. X-ray mirrors are ideal elements for X-ray microscopes because of their high focusing efficiency, lack of chromatic aberration, and resistance to X-ray damage. In recent years, as the need for higher precision increases in industrial imaging technology, X-ray microscopes are also becoming higher resolution, and the use of X-ray mirrors is an essential technology to achieve higher resolution in X-ray microscopes. However, such high-precision X-ray mirror manufacturing technology is largely based on empirical know-how, which increases costs. In addition, although performance degradation due to installation errors is compensated for at the time of use, there is a limit to this as well. In other words, industry needs to develop technology to make high-resolution X-ray microscopes easier to use while keeping manufacturing costs down. Associate Professor Satoshi Matsuyama of Nagoya University’s Graduate School of Engineering has developed a new X-ray mirror technology that can meet exactly these contradictory requests.

Technology

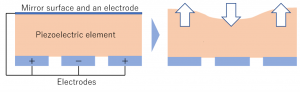

The technology proposed by Matsuyama is an X-ray mirror element for X-ray microscopy that uses piezoelectric material to adjust the surface shape. His innovative idea is to use a single crystal of a piezoelectric material (lithium niobate) as a mirror substrate. This X-ray mirror consists of a mirror substrate made of a single crystal of piezoelectric material, electrodes placed across the substrate, and a reflective surface made of metal deposited on one electrode. When voltage is applied to the electrodes, the piezo material deforms, and this deformation directly changes the shape of the X-ray reflective surface. Using this technique, the electrodes can be placed at narrow intervals and the shape of the X-ray reflective surface can be controlled with nanometer precision.

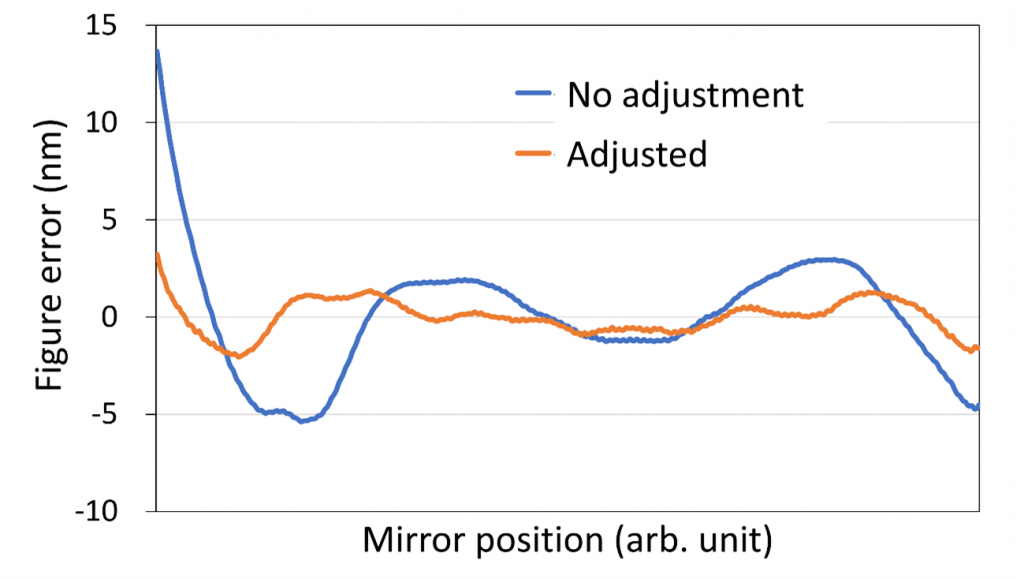

He fabricated and evaluated a prototype X-ray mirror that uses this piezoelectric material as its base. On this prototype mirror, a total of 11 electrodes consisting of a thin gold film, 5 mm wide and 150 nm thick, were placed at 6 mm intervals. The shape error of the mirror surface was measured by measuring the X-rays reflected by this mirror using a grating interferometer. The researchers then confirmed that this mirror deforms the surface of the mirror by about 10-30 pm/V due to the piezoelectric material. Furthermore, the value Peak to Valley, which indicates the surface shape error, was found to improve from 18 nm to 3 nm as a result of the surface correction. In the future, the researchers plan to incorporate this x-ray mirror into an x-ray microscope to verify the extent of the effect, such as improved resolution.

|

|

Proposal of Partnership

Nagoya University is looking for companies interested in developing X-ray mirrors and X-ray microscopes employing this technology. The University is open to collaborative research aimed at demonstrating the technology and developing new X-ray microscopy products. In addition, meetings can be held with researchers to exchange technical information. Nagoya University owns intellectual property related to this technology and can consider licensing it to companies.

Project No. DA-04066