Advantage

- New synthesis process that produces no byproducts, no substances to be removed

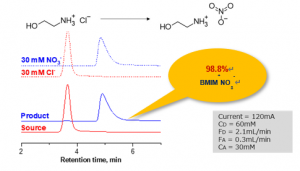

- Purity; >98% (98.8% BMIM+NO3-), average conversion rate of anion and cation sources; 99%

- Nine ionic liquid syntheses have been performed

Background and Technology

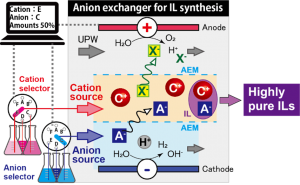

“Ionic liquids”, which consist of a combination of cations and anions and are liquid at room temperature, are said to be a third solvent after water and organic solvents. They are being applied to chemical reactions, separation fields, heat transfer media, and internal battery fluids. The synthesis of ionic liquids (C+A-) requires the preparation and reaction of two raw materials (e.g., C+Cl- and Ag+A-) with counterions of anions (such as OH- and Cl-) and cations (such as H+ and Ag+) that produce water and precipitation, and the resulting by-products (such as AgCl and H2O) must be completely removed to obtain high-purity ionic liquids.

In the process of researching ion extraction devices for dissolved ion analysis, the inventors have developed inline devices for extracting and introducing ions in flowing solutions. From these findings, they have achieved a method for synthesizing ionic liquids by ion displacement, in which anionic ions are introduced at the same time as the anions in the raw solution are removed at the appropriate flow rate by an electric field and membrane permeation. The purity of the ionic liquid obtained by this process was >98%.

In principle, synthesis by substitution of cations and simultaneous introduction of cations / anions are also possible. It is also possible to construct a synthesis system in which a selection valve is incorporated in the pumping system that introduces the solution into the device, and the combination of cations and anions can be freely controlled by a computer. Furthermore, mixed ionic liquids with one cation and several different anions can be synthesized in arbitrary proportions by controlling the amount introduced with the current value.

This ionic liquid production system facilitates the evaluation of various combinations of ionic liquids and the production of small-lot, multi-variety products, and will allow for fundamental research in the development of products using ionic liquids. In addition, the system can be scaled up by making it an array, and an ionic liquid supply system that can be applied to practical scale can be constructed.

|

Data

| Synthesis results of ionic liquids and BMIM+NO3– using this system

|

Patent

Pending

Inventors

Shin-Ichi Ohira, Takashi Toda Faculty of Advanced Science and Technology Kumamoto University

Development Stage

Current stage: We have already synthesized 9 types of ionic liquids and demonstrated high purity and conversion rates.

Next stage: We are looking for collaboration partners from an ionic liquid manufacturer with high purity, on-demand, and flow synthesis needs. We would like to evaluate the performance of this system for the specific ionic liquids requested by each partner, optimize and commercialize the synthesizer for the purpose.

We would be happy to start with a detailed explanation and discussion of the technology.

Product No. ON-04287